| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : PFT

Model Number : OEM

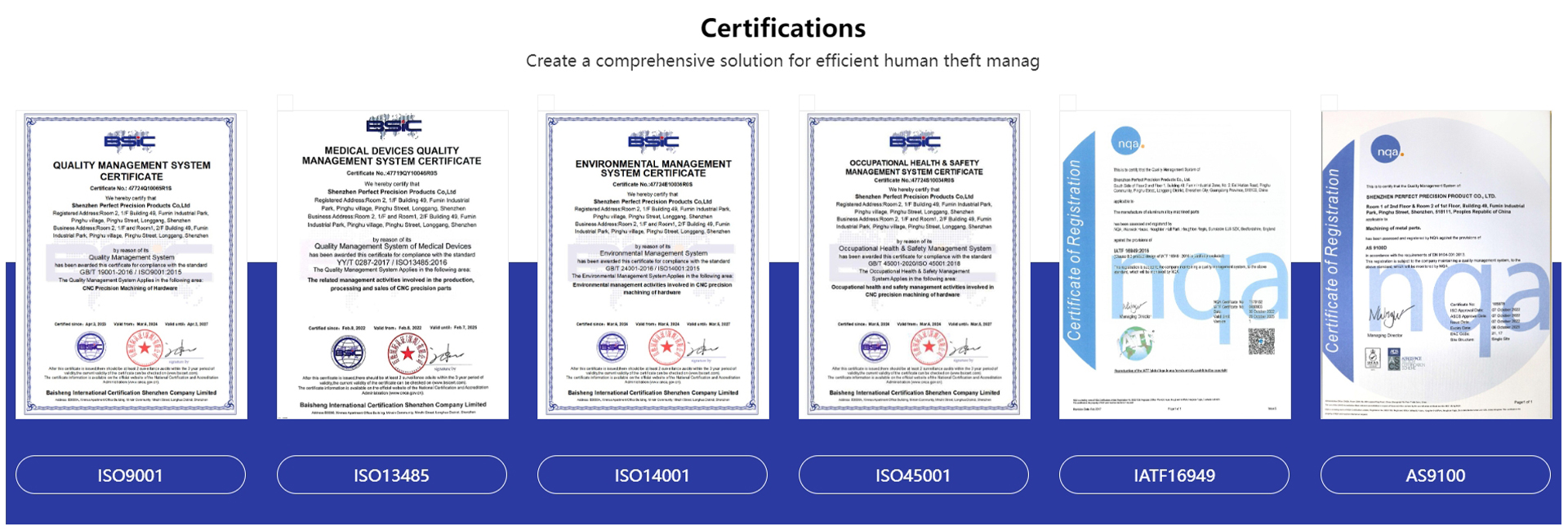

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of custome

Type : Turning

Cnc machining or not : CNC Machining

Service : Customized OEM,OEM ODM

Application : Auto Part,Medical Equipments

Keyword : cnc turning parts

Delivery : Express, Air, Sea, Etc.

Surface Finish : Polishing, Painting, Anodizing, etc.

Diameter : 0.325inch, 0.13inch

Processing : CNC machining

Tolerance : ±0.01mm

Finish : Smooth, Matte, Glossy, etc.

Package : Wood Package Or Carton

Dimensions : Customized Sizes

Quick Delivery Time : 3-15 Days

Materials : Aluminum Alloy Stainless Stell and so on

Quality Control : 100% Inspection

As modern industries continue to evolve, the demand for components with extreme accuracy, strength, and reliability has increased dramatically. From aerospace to medical devices and industrial automation, businesses rely on precision CNC parts to meet tight tolerances and deliver consistent performance under challenging conditions. Among the many manufacturing techniques available, stainless steel turning stands out as a key process for producing these high-performance parts.

What Is CNC Turning?

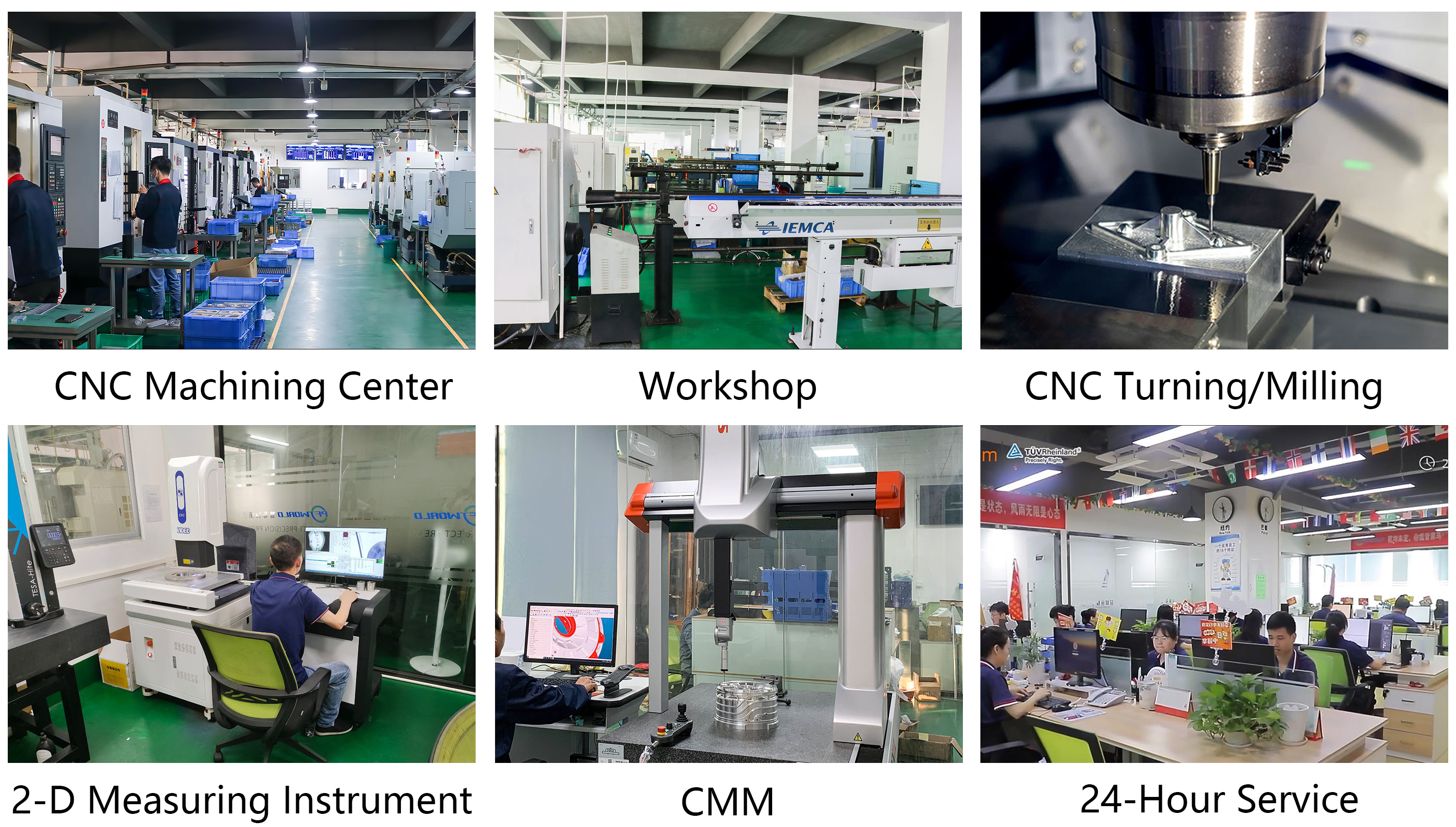

CNC turning is a subtractive machining process where a cutting tool removes material from a rotating workpiece, typically on a lathe. Controlled by computer numerical control (CNC), this method allows for exceptional accuracy and repeatability when machining round or cylindrical parts.

The process is ideal for creating:

When working with stainless steel, CNC turning becomes even more critical due to the material’s strength and resistance to wear and corrosion.

Why Use Stainless Steel for Precision CNC Parts?

Stainless steel is one of the most popular materials for machining due to its unique combination of mechanical and chemical properties:

Commonly used stainless steel grades in CNC turning include:

The Precision Advantage in CNC Turning

Precision CNC parts require machining processes that can consistently achieve tight tolerances—often in the range of ±0.005 mm or tighter. CNC turning is ideal for this level of precision, especially when paired with advanced machinery and skilled operators.

Key benefits include:

Applications of Stainless Steel CNC Turned Parts

CNC turned stainless steel parts are used in a wide range of industries, including:

Enhancing Precision with Secondary Operations

Beyond the core turning process, many precision parts undergo additional treatments or operations:

These steps ensure that the finished part not only meets dimensional requirements but also performs flawlessly in real-world applications.

1. Are you a manufacturer or a trading company?

|

|

Precision CNC parts stainless steel and turning Images |