| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : PFT

Model Number : OEM

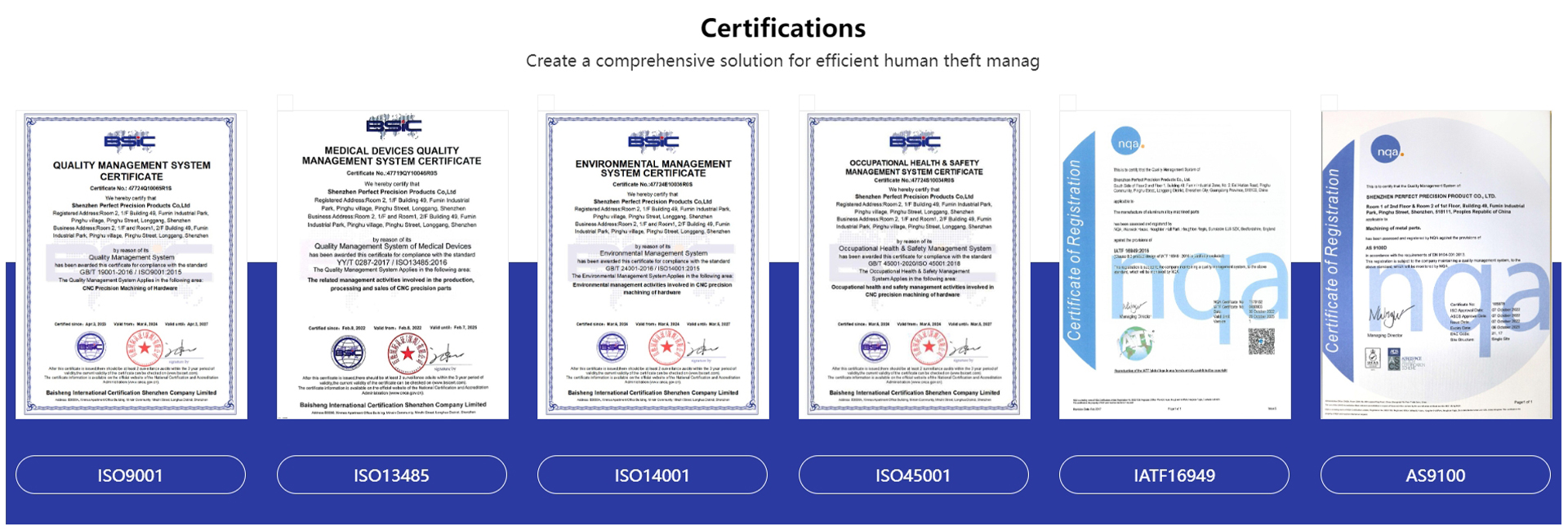

Certification : ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,RoSH,CE etc.

Place of Origin : Guangdong, China

MOQ : 1pcs

Price : $0.48

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 300,000Pcs/ Month

Delivery Time : 7-15 day

Customizable : Yes

Centre Plate : PCB Immersion Gold

Service : OEM/ODM/Customized

Method : CNC machining

Roughness : Ra 0.8a

Sterilization Method : Autoclave

Surface Rough : Ra 0.4a

Surface Disposal : UV coating

Applications : heatsink, medical equipment

Usage : Medical

Type : Equipment

Protection Level : IP65 static / IP54 dynamic

Size : Customized

Surface Roughness : According To Customer Needs

Equipements : CNC Punch, CNC bend, Laser cut

In today’s fast-evolving medical industry, precision isn’t just a requirement—it’s a lifeline. At PFT, we specialize in crafting precision CNC medical parts and surgical-grade components that set new benchmarks for reliability, safety, and performance. As a ISO 13485-certified custom manufacturer, we blend cutting-edge technology with uncompromising quality control to deliver components that surgeons trust and patients deserve.

Medical devices demand perfection. A microscopic flaw in a bone screw or implant can compromise patient outcomes. Our CNC machining processes leverage multi-axis technology and aerospace-grade materials (like titanium, PEEK, and 316L stainless steel) to achieve tolerances as tight as ±0.001" . Whether you need robotic surgery components, dental fixtures, or diagnostic equipment parts, our solutions ensure:

"In medical manufacturing, precision isn’t optional—it’s ethical."

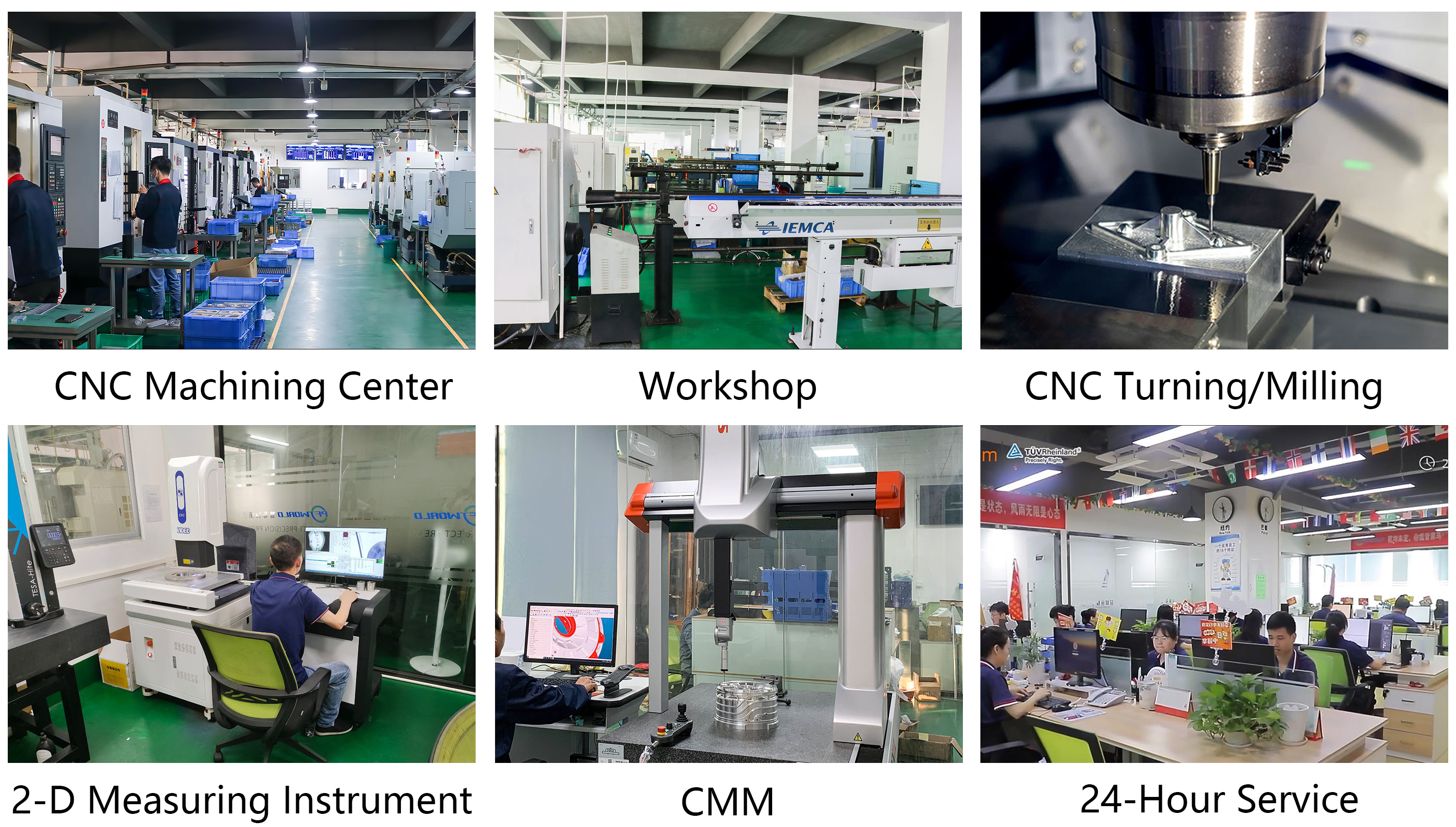

Our facility houses Swiss-style CNC lathes, 5-axis milling centers, and EDM machines, enabling us to produce complex geometries—from micro-scaled surgical tools to custom orthopedic implants. Real-time monitoring systems guarantee every component meets ASTM F899 and ISO 13485 standards .

We machine over 20+ materials, including:

| Material | Applications | Key Advantages |

|---|---|---|

| Medical-Grade Titanium | Implants, Trauma Plates | Lightweight, Osseointegration |

| PEEK Polymers | Spinal Cages, Instruments | Radiolucency, Durability |

| 316L Stainless Steel | Surgical Trays, Clamps | Sterilization Resilience |

| Custom surface treatments—passivation, electropolishing, or anodizing—enhance functionality and longevity . |

Every batch undergoes:

Need a prototype in 72 hours or high-volume production? Our engineers excel at:

A leading robotics firm approached us to create titanium end-effectors for a new surgical platform. Challenges included:

"We don’t just make parts—we enable medical breakthroughs."

From CNC-turned biopsy needles to custom implantable components,PFT combines surgical-grade precision with scalable manufacturing. Request a quote or upload your drawings for a free DFM analysis today.

1. Are you a manufacturer or a trading company?

|

|

Roughness Ra 0.8a Precision CNC Medical Parts for Surgical-Grade Components Custom Surface Roughness Images |